Wood plastic composite (WPC) products have taken the global outdoor decor market by storm. From durable WPC fencing to seamless composite decking, homeowners, architects, and contractors alike are choosing these materials for their impressive durability, water resistance, and low maintenance.

However, not all WPC products are created equal. In fact, the market is flooded with products that look similar but vary significantly in quality—and lifespan. Some may last for over a decade, while others may crack, fade, or deform in just a few months.

If you're planning to invest in wood plastic products, it’s crucial to know how to identify the good from the bad. In this guide, we’ll uncover the top five ways to quickly spot quality WPC products, explain how raw materials affect performance, and help you make smarter choices for your project—without falling for cheap imitations.

WPC is a material made from a blend of wood fibers and plastic, offering a hybrid of natural texture and man-made durability. Its popularity has exploded in recent years, especially in China, as a cost-effective solution for:

Outdoor decking

Garden fences

Cladding panels

Park benches

Outdoor staircases

Thanks to its resistance to corrosion, water, acid, pests, and UV rays, WPC requires little maintenance, making it ideal for residential and commercial projects alike.

But here's the catch: many first-time buyers don’t realize that price differences in WPC products often reflect major quality gaps. Lifespan differences can range from a few months to over 10 years, depending on how the product is made.

Want to dig deeper into this issue? Check out this article on Unveiling the Mystery of Guardrail Price Variations.

Wood powder is a core ingredient in WPC. Finer particles (higher mesh count) result in better bonding with the plastic, creating smoother, more uniform surfaces. High-quality WPC manufacturers use fine wood powder for better consistency, while cheaper factories cut costs by using coarse wood powder, leading to rough finishes and structural weakness.

PE is the plastic component of WPC. While high-quality PE pellets ensure product stability and strength, some manufacturers use recycled waste plastics to save money. These low-grade plastics result in uneven textures, increased brittleness, and reduced weather resistance.

Tip: Low-quality PE also leads to poor powder coating and higher water absorption—ultimately increasing the risk of cracking or swelling.

Some premium manufacturers go the extra mile by using Surlyn, an advanced additive found in golf balls, to significantly boost hardness, impact resistance, and wear durability. Learn how advanced additives are reshaping WPC performance in 2025.

Even if you’re not a materials expert, you can visually inspect WPC products to assess their quality. Here's how:

High-quality: Smooth, slightly glossy, oily texture, no cracks.

Low-quality: Rough, dull surface, no oil sheen, visible microcracks from poor PE extensibility.

High-quality: Glossy finish, uniform fine wood powder particles.

Low-quality: Dull finish, visible large and uneven wood powder particles.

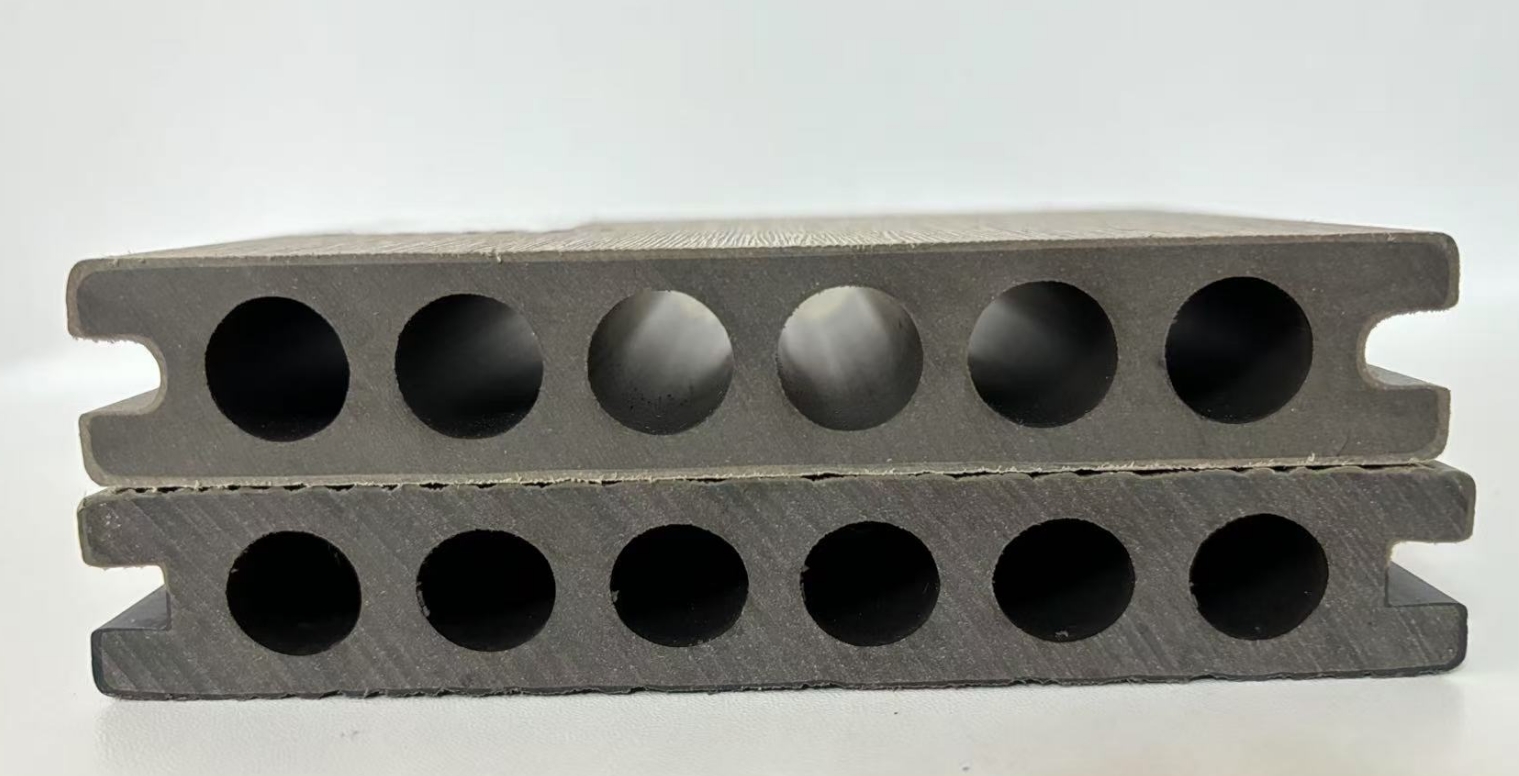

High-quality: Dense, solid structure, consistent fine particles.

Low-quality: Loose structure, rough texture, uneven distribution, visible wood fibers.

Would you like to know the differences between the co-extruded WPC material and the earlier versions? Please refer to this detailed explanation about the five key differences between the co-extruded deck and the first-generation WPC deck.

The WPC industry has evolved rapidly in the last decade. As competition intensifies, some factories race to the bottom by sacrificing material quality for lower pricing. While this strategy can cut costs in the short term, it leads to a flood of fragile, low-quality products in the market.

Many customers are new to WPC and may not realize that paying a slightly higher price for quality materials could save thousands in repair, replacement, and maintenance costs later.

For those looking into outdoor fencing options, here’s a helpful guide on How to Choose the Best WPC Fencing.

Don’t judge a product by looks alone. High-quality WPC products are also safer. For example, some advanced products are:

Slip-resistant

Flame-retardant

Free from sharp burrs

Structural-load tested

Environmentally friendly

Read this article on the 5 Essential Safety Features of WPC Patios to learn more about hidden quality signals.

Wood plastic products offer many advantages, but only if you choose the right ones. By understanding the raw materials, production quality, and visual cues, you can avoid low-grade products that waste your time and money.

Remember these golden rules:

Finer wood powder = better bonding and smoother surface

Pure PE = stable strength and weather resistance

Additives like Surlyn = enhanced durability

Visual signs of quality = smooth, glossy, crack-free finishes

Reputable suppliers = consistent, long-lasting products

If you’re unsure, always ask for samples, compare cross-sections, and don’t hesitate to discuss raw materials and manufacturing techniques with your supplier.

praysunmaterials@gmail.com