When selecting the ideal material for a project or property, it is crucial to consider the key characteristics of the material. In recent years, wood-plastic composites (WPC) have attracted wide attention in construction and outdoor applications due to their durability and low maintenance. However, there are often questions about the water resistance of the WPC . This article will discuss in depth the waterproof properties of WPC, composition, advantages, limitations, and actual performance in different applications.

One, What is wood plastic composite material?

Wood plastic composite material is made of wood fiber or wood powder and thermoplastic mixed materials. wood components are typically derived from recycled wood waste or byproducts of wood production, , while plastic components may consist of recycled or unprocessed polyethylene, polypropylene, or PVC. By heating and mixing the ingredients the resulting compounds are then extruded or formed into the desired shapes to create a new kind of material that combines the aesthetic appeal and warmth of wood with the durability and weather resistance of plastic.

Two, wood plastic material water resistance

Although WPC is often marketed as a waterproof material is not completely waterproof. Its water resistance is affected by many factors, including composition ratio, manufacturing process, surface treatment and raw material quality. The water absorption rate of high quality wood plastic products under normal conditions is usually less than 1-3%, is much lower than the 20-30% water absorption rate of untreated wood. Therefore, although WPC is not 100% waterproof, its superior durability still makes it the first choice in the current waterproof materials.

Three, the advantages of wood plastic board water resistance

Compared with traditional wood products, wood plastic waterproof performance has the following advantages:

Reduce expansion and warping: wood plastic is not easy to change size due to moisture absorption, can maintain its shape and structural integrity.

Improved durability: limited water absorption helps protect WPC from damage such as rot, pests, and prolongs service life.

Lower maintenance requirements: There is no need for regular sealing or waterproofing as with natural wood.

Better in wet environments: suitable for areas with high humidity or constant contact with water.

Four, the limitations of water resistance of wood plastic materials

Despite the many advantages of WPC, , there are still some limitations when it comes to waterproofing:

Not completely waterproof: long-term exposure to water may still absorb some moisture.

Possibility of mold and mildew: In humid environments with poor air circulation may support mold and mildew growth.

Fading: Prolonged exposure to moisture and sunlight may cause fading or discoloration.

Thermal expansion: although to a lesser extent, may still expand and contract with temperature changes, resulting in cracks or loosening of fasteners.

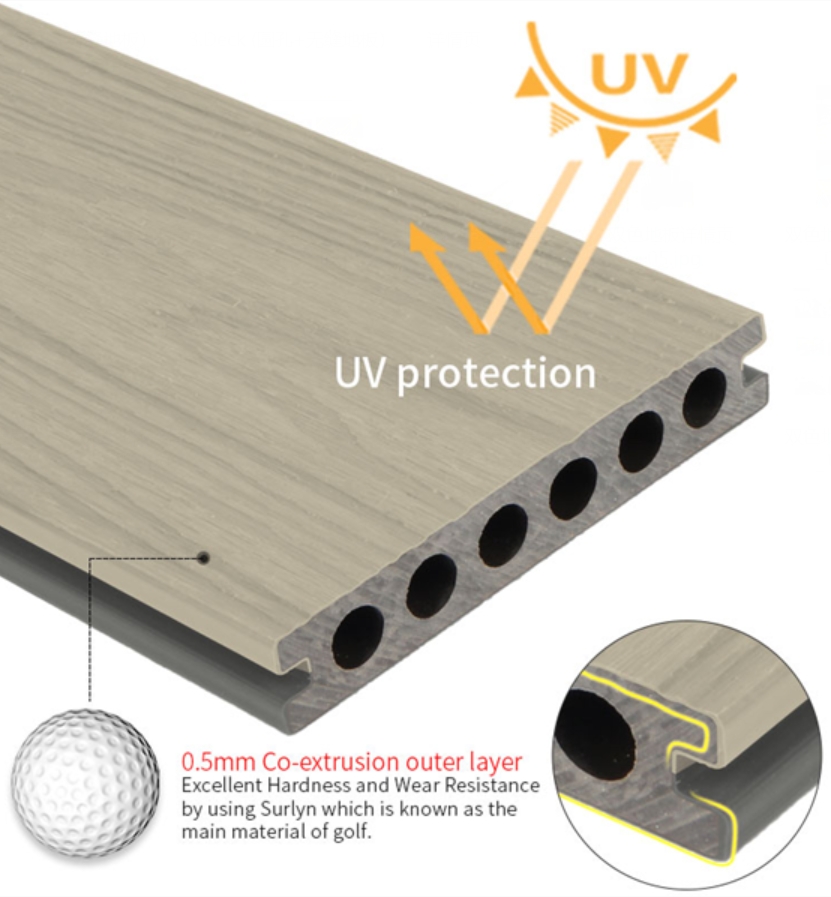

Praysun's innovative solutions

To improve the limitations of WPC materials, Praysun's experts have innovated on the basis of traditional WPC materials. A layer of surlyn , also used on golf balls, greatly improves the water and weather resistance of WPC products. This innovation gives Praysun's WPC products significant advantages in terms of maintenance, durability and cost effectiveness.

With these ideas in mind, the waterproof properties of WPC composites can work in many different ways, which is well worth keeping in mind as part of your final decision on the right material. At present, Prayusn's wpc deck, wpc fence, etc., have been widely used in hydrophilic buildings, such as swimming pool level, park lake boardwalk and seaside pier.

If you think WPC can be a good fit for your needs, our team of experts at Praysun can help you, click on www.praysun.com right away, or contact us at praysunmaterials@gmail.com

praysunmaterials@gmail.com